Floating Offshore Wind Mooring

The new market for floating offshore wind mooring is expected to increase significantly in the years to come with the increased use of floaters as foundations for offshore wind turbines.

Offshore Wind Design aim to provide innovative and cost-effective foundation, mooring and anchoring products and services for this floating offshore wind mooring market.

The technologies and products we will provide for floating offshore wind mooring are:

Floating Offshore Wind Mooring Systems

Offshore Wind Design also provides early-stage engineering and design services for the developers within research and development, feasibility and FEED studies and concept development and product technology qualification.

In addition, we also provide standard CAD modelling, subsea engineering and design services, such as structural, geotechnical, materials and corrosion engineering.

The mooring systems to be used for floating offshore wind are currently taken from the offshore oil and gas industry where these have been used as anchoring of floating platforms and drilling rigs for many decades. The main mooring systems used are tension leg mooring or Tension Leg Platform (TLP), Taut angle mooring lines (or semi-taut) and the most common mooring solution, using slack catenary mooring lines.

.

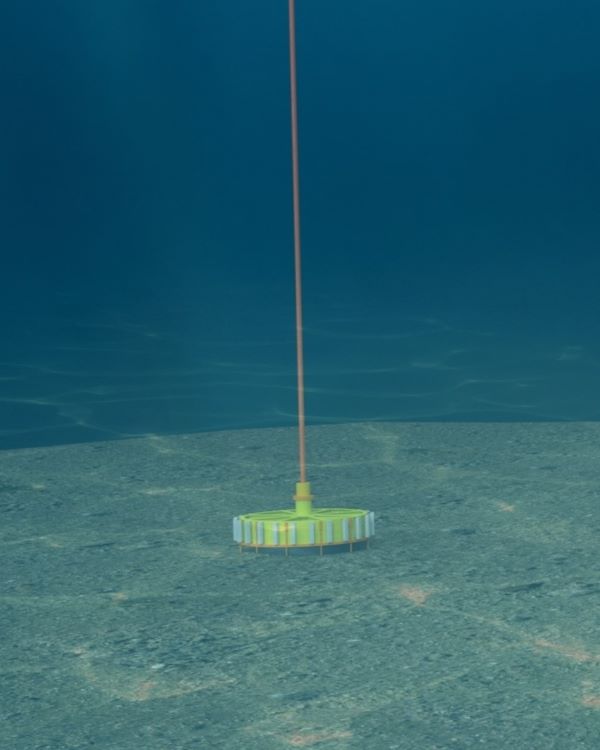

Suction and Gravity Anchor Mooring for Floating Wind Turbines

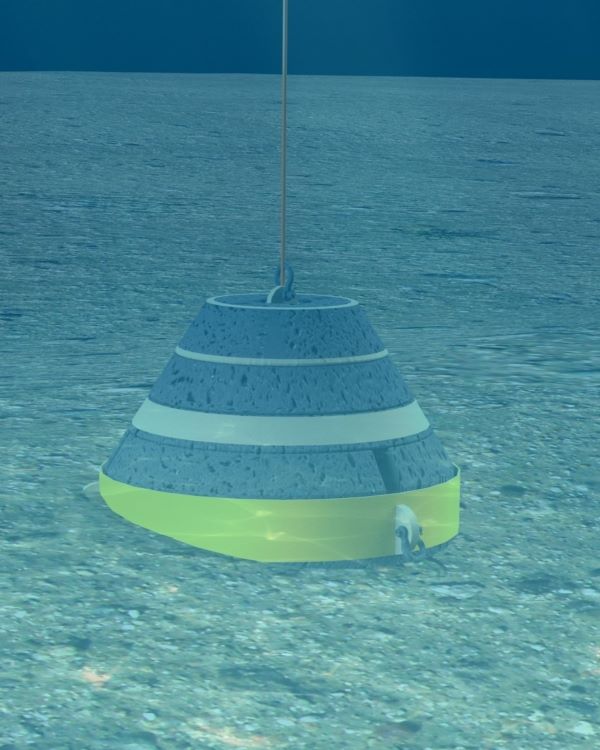

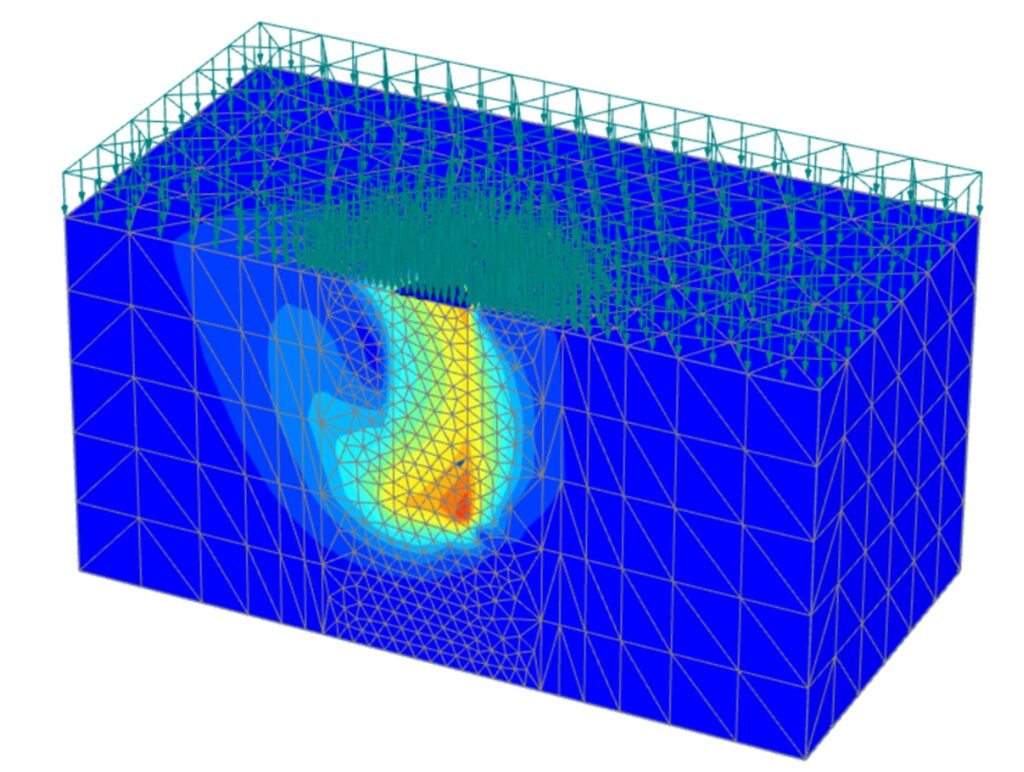

Suction anchors have been used for catenary mooring in soft to very soft soil conditions since the early 1990s. These seabed conditions are often seen in deep water and near river deltas where soft clay dominates. Suction anchors also require a certain water depth to establish the necessary underpressure or suction required to force the caisson into the seabed. Our new patent pending innovative TLP suction anchor now also makes these the most commercially viable solution also for tension leg mooring (TLP) mooring systems. The new TLP suction anchor innovation increases the load capacity, most for near vertical long term sustained loads, such as pre-loads for TLP floaters. This could significantly reduce the cost of the floating mooring system.

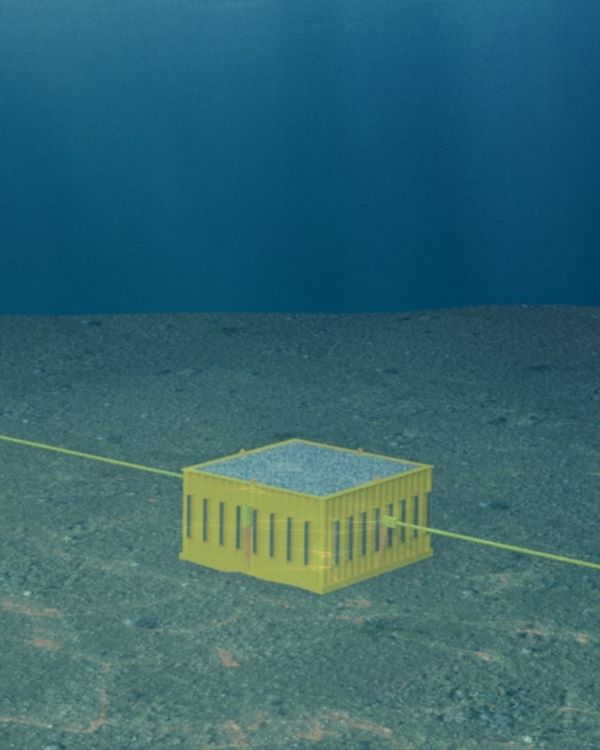

In soil conditions where suction anchors cannot penetrate, gravity anchors can be used as floating offshore wind mooring. This is often in shallower waters where sand and even bedrock seabed dominates or in complex layers with sand and clays. Offshore Wind Design provide a new and innovative gravity anchor design that provide easy and cost effective installation, accurate positioning with no need for a holding capacity proof test.

Using Low Friction Paint to Ease Installation

Offshore Wind Design also has a new patent pending innovation that include using a low friction paint, film or coating to lower the penetration resistance of suction anchors, both permanently and temporarily. This innovation can be used to reduce the cost of single suction anchors or to increase the load capacities when required. By reducing the penetration resistance and required suction, reduction in vessel time can also give significant cost savings.

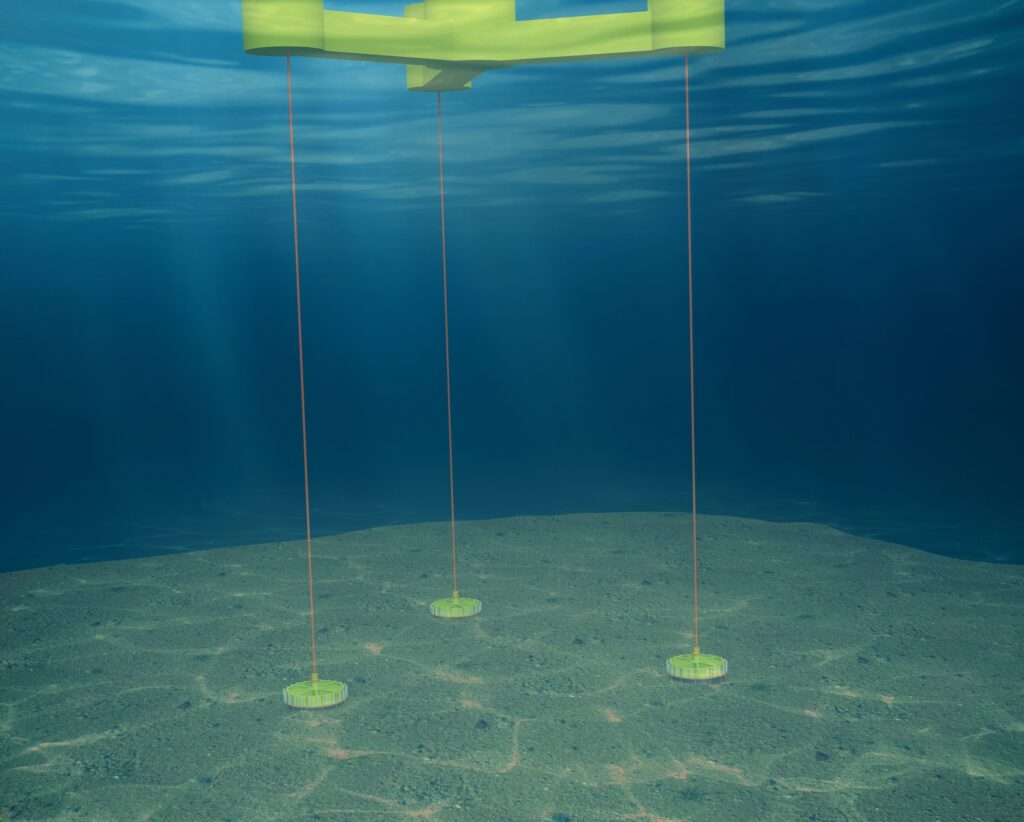

Fishing Friendly Floating Offshore Wind Mooring Design

One of the major challenges for floating offshore wind mooring is that today’s wind farm system design limits or even totally exclude the fishing activities within the wind farm perimeter. This could create conflict between the fisheries and the wind farm development. Offshore Wind Design has a fishing friendly offshore wind farm system design based on experience from the subsea oil and gas industry that could make wind farms and fisheries coexist without conflict and where the wind farm mooring facilities would even contribute to better conditions for life under water.